Internal Rotary Inspection System or in short IRIS is among the most popular tube inspection techniques in the world which is widely used in Petrochemical plants. This technique is based on Ultrasonic immersion testing method which utilized a high frequency longitudinal transducer to measure various tube materials, even plastic.

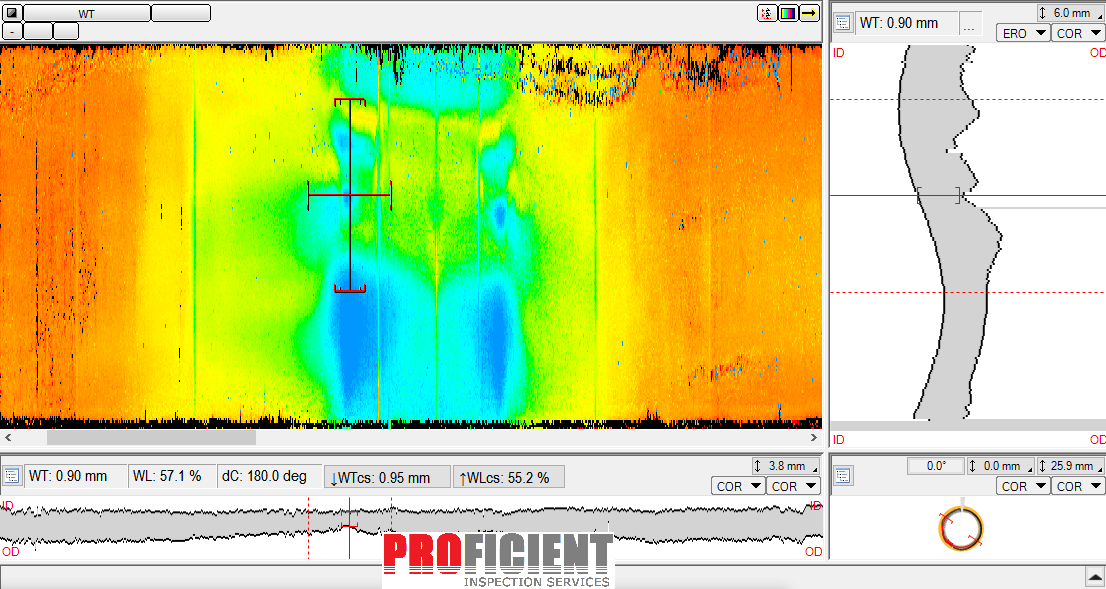

Because it is an ultrasonic testing technique, it requires water as a couplant which is why the tubes must be filled with water during the test. IRIS provides information on the actual remaining thickness of the tubes plus able to differentiate between internal and external defects by analyzing on all B-scans, C-scans and D-scans as shown in figure below.

IRIS is most suitable to detect erosion, corrosion, baffle wear, and even pitting. Contact us for more detailed explanation on the technique!